-

Manufacture, sales, servicing and maintenance of CNC lathes and peripheral equipment

TAKAMAZ products that “hit the right spot”, including one of the smallest 6-inch chuckers in the world and machines for emerging countries that are easy for female workers to operate, are at work in a variety of fields both in Japan and overseas. We have also been working on automation ahead of other manufacturers, and have developed our own peripheral devices such as robots, and equipment for measurement, cleaning, and box packing; our strength is customized technology that can build entire production lines. In addition, we produce original collet chucks, and take responsibility for them right through from ordering to manufacturing and following up afterwards. It is very rare for a company to provide everything originally, and high-quality, high-precision TAKAMAZ products that meet exacting requirements are highly trusted by our customers.

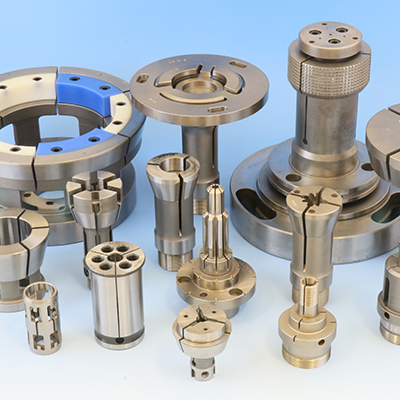

Collet Chuck

Generally speaking, a chuck is like a hand on the spindle, used when mounting a workpiece on the spindle. Those chucks that are able to grasp bars of a specific diameter and allow one-touch setup are called collet chucks. TAKAMAZ differentiates itself by manufacturing special collets that are able to grasp irregularly shaped workpieces.

-

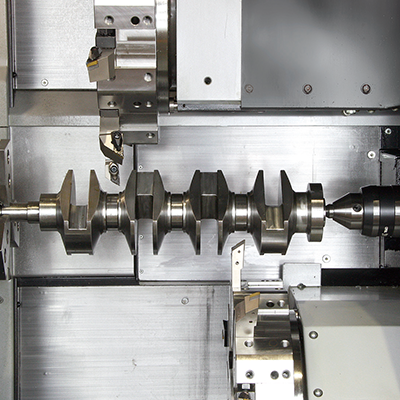

Automobile Part Machining

TAKAMAZ has also made inroads into automobile part machining. We manufacture engine parts such as “starter housings” and “end frames” on automated lines built using our products, and in recent years have also machined pressure sensor parts for air conditioners. We strive to provide products that meet customer requirements with a total production system from order to shipment and thorough quality control and delivery management. (The production factories are located in Ishikawa and Thailand.)

-

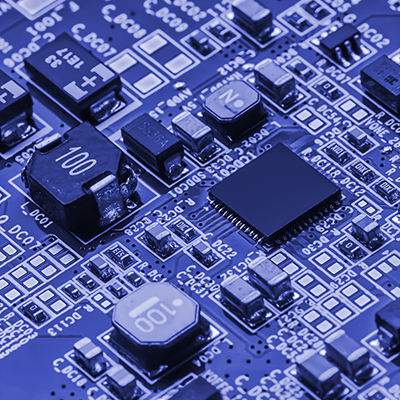

IT-related Manufacturing Equipment

TAKAMAZ is actively moving ahead with IT-related project in order to build them into a mainstay of its business alongside machine tools and automobile part machining. The Development Center has a clean room that comprehensively manages the environmental conditions and air cleanliness, and produces manufacturing equipment related to liquid crystals and semiconductors, equipment for FPC substrates, and equipment for glass processing. In recent years, we have also developed a life science business, and we are carrying out varied research to create new social value.

-

Other Businesses

Incorporating the technology and know-how cultivated in the field of manufacturing lathes and automatic conveying equipment, we have developed the world's first automatic and semi-automatic machines with gingko nut shell cracking and deshelling functions. Our automatic thin skin peeling machine for garlic and the clove separator that breaks up the bulbs have been highly acclaimed. One of our plans for the future is to create a variety of machines that will reduce the burden on producers and processors and improve efficiency while also looking at food serving machines that make use of our knowledge about industrial robots.